Slings

ADVANTAGES OF VIKING WEB SLINGS

- Light weight and excellent flexibility allow safer and easier handling of your valuable products.

- Slings are non-slippery.

- Strong Resistance to chemical and oil.

- Various sizes available for every application.

- Slings for use in specific application can be made on customer’s request.

- Long life and economy prices as slings are made of the strongest high tenacity materials.

- Excellent resistance to surface abrasion by special treatment on surface.

- Various color.

- Perfect quality control by thorough experiment.

- Stamping on the surface available.

NYLON, POLYESTER WEBBING

| WIDTH (Inches) |

TENSILE (LBS) |

TENSILE (LBS) |

TENSILE (LBS) |

TENSILE (LBS) |

| 1’ | 9,800 | 7,500 | 6,800 | 5,000 |

| 2’ | 19,600 | 15,000 | 13,600 | 10,000 |

| 3’ | 29,400 | 22,500 | 20,400 | 15,000 |

| 4’ | 39,200 | 30,000 | 27,200 | 20,000 |

| 6’ | 58,800 | 45,000 | ||

| 8’ | 78,400 | 60,000 | ||

| 10’ | 98,000 | 75,000 | ||

| 12’ | 117,600 | 90,000 |

BREAKING LOAD & SAFETY WORKING LOAD

VIKING (Eye to Eye Type)

|

ITEM

1 |

WIDTH

(INCHES) |

STRAIGHT

(LBS) |

CHOCKER

(LBS) |

BASKET

|

ADJ. ULTI

|

ULTIMATE

|

|

|

SINGLE

PLY |

TWO

PLY |

||||||

|

|

|

||||||

|

|

|

||||||

|

NYLON POLYESTER

|

1’

|

2,700

|

2,100

|

5,400

|

10,800

|

13,500

|

18,000

|

|

2’

|

5,400

|

4,200

|

10,800

|

21,600

|

27,000

|

36,000

|

|

|

3’

|

8,100

|

6,300

|

16,000

|

32,400

|

40,500

|

54,000

|

|

|

4’

|

10,800

|

8,100

|

21,600

|

43,200

|

54,000

|

72,000

|

|

|

6’

|

16,200

|

12,600

|

32,400

|

64,800

|

81,000

|

108,000

|

|

|

8’

|

21,600

|

16,800

|

43,200

|

86,400

|

108,000

|

144,000

|

|

|

10’

|

27,000

|

21,000

|

54,000

|

108,000

|

135,000

|

180,000

|

|

|

12’

|

32,400

|

25,200

|

64,800

|

129,600

|

162,000

|

216,000

|

|

VIKING (Endless Type)

| ITEM 2 |

WIDTH (INCHES) |

STRAIGHT | CHOCKER | BASKET | ADJ. ULTI | ULTIMATE | |

|

SINGLE PLY

|

TWO

PLY |

||||||

|

|

|

||||||

|

|

|

||||||

|

NYLON POLYESTER

|

1’ |

5,400

|

4,200

|

10,800

|

21,600

|

27,000

|

36,000

|

| 2’ |

10,800

|

8,400

|

21,600

|

43,200

|

54,000

|

72,000

|

|

| 3’ |

16,200

|

12,600

|

32,400

|

64,800

|

81,000

|

108,000

|

|

| 4’ |

21,600

|

16,800

|

43,200

|

86,400

|

108,000

|

144,000

|

|

| 6’ |

32,400

|

25,200

|

64,800

|

129,600

|

162,000

|

216,000

|

|

| 8’ |

43,200

|

33,600

|

86,400

|

172,800

|

216,000

|

288,000

|

|

| 10’ |

54,000

|

42,000

|

108,000

|

216,000

|

270,000

|

360,000

|

|

| 12’ |

64,800

|

50,400

|

129,600

|

259,200

|

324,000

|

432,000

|

|

SAFETY FACTOR 5:1

- SAFETY WORKING LOAD WILL BE 1/5 OF ULTIMATE BREAKING STRENGTH IN 1PLY SLING

- ULTIMATE : BREAKING LOAD

- METHOD ADJ ULTI = ULTIMATE B/S = 0.75

ADJ ULTIMATE BREAKING STRENGTH : TEST WORKING CONDITION AROUND A LOAD, OUTSIDE PLY MUST STRETCH FORTH THAN INSIDE (WHEN PULLING TO DESTRUCTION THE OUTSIDE PLY WILL DESTRUCT FIRST)

- METHOD SWL = ADJ B/S (1/5)

- STANDARD COLOR: YELLOW

- METHOD CHOCK SWL = SWL 0.75

| STANDARD PRODUCTS | |

| VIKING |   |

| VIKING |   |

SAFETY WORKING LOAD ACCORDING TO ANGLE

VIKING (Eye to Eye Type)

|

ITEM

|

WIDTH (INCHES)

|

0º

|

30º

|

45º

|

60º

|

90º

|

120º

|

|

100%

|

95%

|

90%

|

85%

|

70%

|

50%

|

||

|

|

|

|

|

|

|

||

|

NYLON POLYESTER

|

1’ |

5,400LBS

|

5,100LBS

|

4,800LBS

|

4,500LBS

|

3,750LBS

|

2,700LBS

|

| 2’ |

10,800

|

10,200

|

9,600

|

9,000

|

7,500

|

5,400

|

|

| 3’ |

16,200

|

15,300

|

14,400

|

13,500

|

11,250

|

8,100

|

|

| 4’ |

21,600

|

20,400

|

19,200

|

18,000

|

15,000

|

10,800

|

|

| 6’ |

32,400

|

30,600

|

28,800

|

27,000

|

22,500

|

16,200

|

|

| 8’ |

43,200

|

40,800

|

38,400

|

36,000

|

30,000

|

21,600

|

|

| 10’ |

54,000

|

51,000

|

48,000

|

45,000

|

37,500

|

27,000

|

|

| 12’ |

64,800

|

61,200

|

57,600

|

54,000

|

45,000

|

32,400

|

VIKING (Endless Type)

|

ITEM

|

WIDTH

(INCHES) |

0º

|

30º

|

45º

|

60º

|

90º

|

120º

|

| 100% |

95%

|

90%

|

85%

|

70%

|

50%

|

||

|

NYLON POLYESTER

|

1’ |

10,800LBS

|

10,200LBS

|

9,600LBS

|

9,000LBS

|

7,500LBS

|

5,400LBS

|

| 2’ |

21,600

|

20,400

|

19,200

|

18,000

|

15,000

|

10,800

|

|

| 3’ |

32,400

|

30,600

|

28,800

|

27,000

|

22,500

|

16,200

|

|

| 4’ |

43,200

|

40,800

|

38,400

|

36,000

|

30,000

|

21,600

|

|

| 6’ |

64,800

|

61,200

|

57,600

|

54,000

|

45,000

|

32,400

|

|

| 8’ |

86,400

|

81,600

|

76,800

|

72,000

|

60,000

|

43,200

|

|

| 10’ |

108,000

|

102,000

|

96,000

|

90,000

|

75,000

|

54,000

|

|

| 12’ |

129,600

|

122,400

|

115,200

|

108,000

|

90,000

|

64,800

|

|

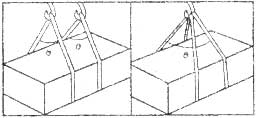

Please choose most proper sling of adequate length and breaking load for the weight and shape of transported goods (the bigger the angle of sling is, the less the maximum working load is)

|

RELATION BETWEEN DAMAGE AND STRENGTH

Crosswise damage on surface

|

Extent of Damage

|

Remaining strength (%)

|

|

|

1/5 damaged

|

50

|

|

|

1/3 damaged

|

40

|

|

|

1/2 damaged

|

30

|

|

Damage and horizontally inward

|

Extent of Damage

|

Remaining strength (%)

|

|

|

1/3 damaged

|

60

|

|

|

1/2 damaged

|

40

|

|